Subcontracting & Outsourced Manufacturing

Fill out the form to request information

Manage and Control Subcontractor Activities with Fluentis Outsourcing Management

Streamlined Features for Simplifying Outsourcing Processes

The Fluentis Outsourcing Management module enables the creation of subcontracting orders either manually from production or automatically by confirming reorder proposals generated through requirements analysis procedures.

Once orders are sent to subcontractors, the module handles the issuance of shipping documents for materials, accounting for both materials supplied directly to subcontractors and their inventory in stock. Additionally, it manages the recording of purchase delivery documents, which update the subcontractor’s inventory records accordingly.

Fully integrated with the bill of materials (BOM), the module allows for efficient tracking of return codes for subcontracted items and organizes the return process.

This functionality also integrates with pricing management, enabling price assignment by item code or by item code and phase, ensuring flexibility and precision.

Strenghts

Automatic generation of subcontracting orders from planning.

Management of subcontracting with bill of materials or by phase.

Automatic processing of documents.

Subcontracting returns management, including handling of returns.

Management of subcontractor price lists by item code and work phase.

Tracking of inventory held at subcontractor warehouses.

Subcontracting with Code Change and Phase Subcontracting

Fluentis ERP simplifies and optimizes subcontracting management, allowing for production organization through external companies. There are two operational modes: code change subcontracting and phase subcontracting.

In the first case, when creating the bill of materials, the parameters necessary to identify the information related to external processing are defined for the components of the item. In the second case, during the production cycle, it is possible to specify whether a phase is performed internally or externally. Based on the external supplier’s parameters, they will be tasked with performing the external processing. Once the semi-finished goods are returned, the materials are removed from the supplier’s inventory and the semi-finished goods are automatically loaded into the central warehouse.

If the company does not have internal production, the subcontracting environment can be configured to manage deliveries between external suppliers. In this context, all operations are performed by subcontractors, with delivery occurring between them at the end of each processing stage.

What our customers say about Fluentis

Con Fluentis ERP abbiamo introdotto in Italtecnica una gestione integrata di tutte le aree aziendali migliorando significativamente la nostra reattività nel soddisfare le esigenze dei clienti, nella raccolta dati sul campo sia in ambito produttivo che logistico. Nell’ambito industriale è stata fondamentale la capacità di Fluentis di permetterci di disegnare i nostri processi e Work Flow, anche in autonomia, e l’integrazione con gli impianti in ottica Industry 4.0

- Filippo Bollettin, IT Manager

Italtecnica Srl

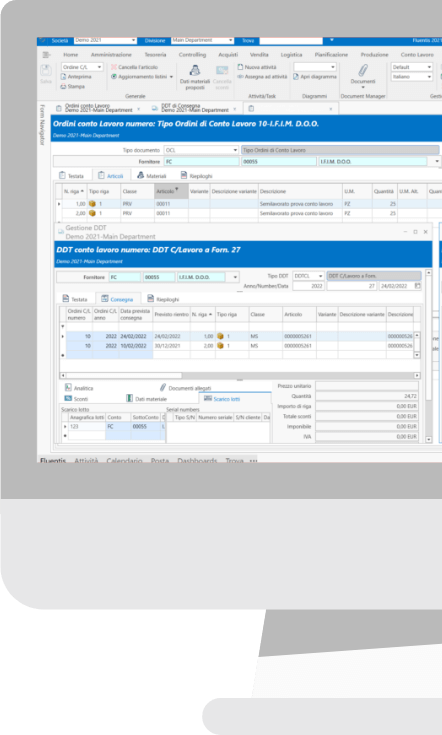

Subcontracting Orders

Subcontracting orders can be manually entered or automatically generated from the Production Scheduler (MS) processing. A subcontracting order, which is similar to a supplier order, has specific characteristics such as indicating the quantities of semi-finished goods to be produced, the amounts of material to be used, and the quantities of material to be delivered to the subcontractor based on actual inventory levels. Additionally, it defines information such as the turnaround times for the return of the processed materials.

Features

- Management of subcontracting orders, including details of materials to be delivered, used, and returned.

- Automatic generation of subcontracting orders from planning.

Subcontracting Delivery Note (DDT)

With this procedure, it is possible to fulfill the subcontracting order and create a delivery note (DDT) for the material delivered to the subcontractor. The goods are then deducted from the central warehouse and tracked in the subcontractor’s warehouse. It is possible to manage a single warehouse that consolidates all subcontractors, labeled as “Goods at third parties,” and define stock levels based on the “subaccount” key for each subcontractor.

Features

- Delivery note (DDT) for subcontractors, fulfilling the issued subcontracting orders.

Subcontracting Returns

The returns management process allows you to load the finished goods into the central warehouse and deduct the materials consumed by the subcontractor during their production process. Any production waste is also recorded at this stage.

Features

- Management of returns from subcontractors, with indication of the returned quantities.

- Fulfillment of the subcontracting order.

- Automatic generation of the invoice.

Subcontractor Price Lists

This procedure allows you to define the rates at which the subcontractor is assigned to process semi-finished goods. You can set a price for each type of “processing phase” within the context of a specific type of semi-finished product.

Features

- Management of subcontractor price lists by item code and processing phase.

- Tiered pricing management.

- Duplication and maintenance of price lists.

Discover how Fluentis ERP

can transform your business

15-day free trial | No automatic renewal | Instant access

Contact us for more information

Get in touch with us if you:

- Are a SMB in Manufacturing, Distribution, or Services

- Need to streamline and digitalize your business processes

- Want to take advantage of the benefits of a native cloud solution

- Want to replace your non-integrated softwares with a unified ERP platform

+1 281 404 1726

Chat with us