Improve your Production Management to make your Business more competitive

Control and Manage Production for Maximum Efficiency

Fluentis ERP’s Production Management module enables manufacturers and industrial companies to handle all operational aspects of production, even in complex environments, including cost estimation, cost accounting, materials, and activities.

Fluentis’ algorithms allow you to manage all internal and external business processes across the entire product lifecycle, from cost estimation to design, material and resource procurement, production scheduling (both internal and subcontracted), production data collection, and cost control. This also includes integration with Industry 4.0 concepts for production plants and automated warehouses.

Modules and Features

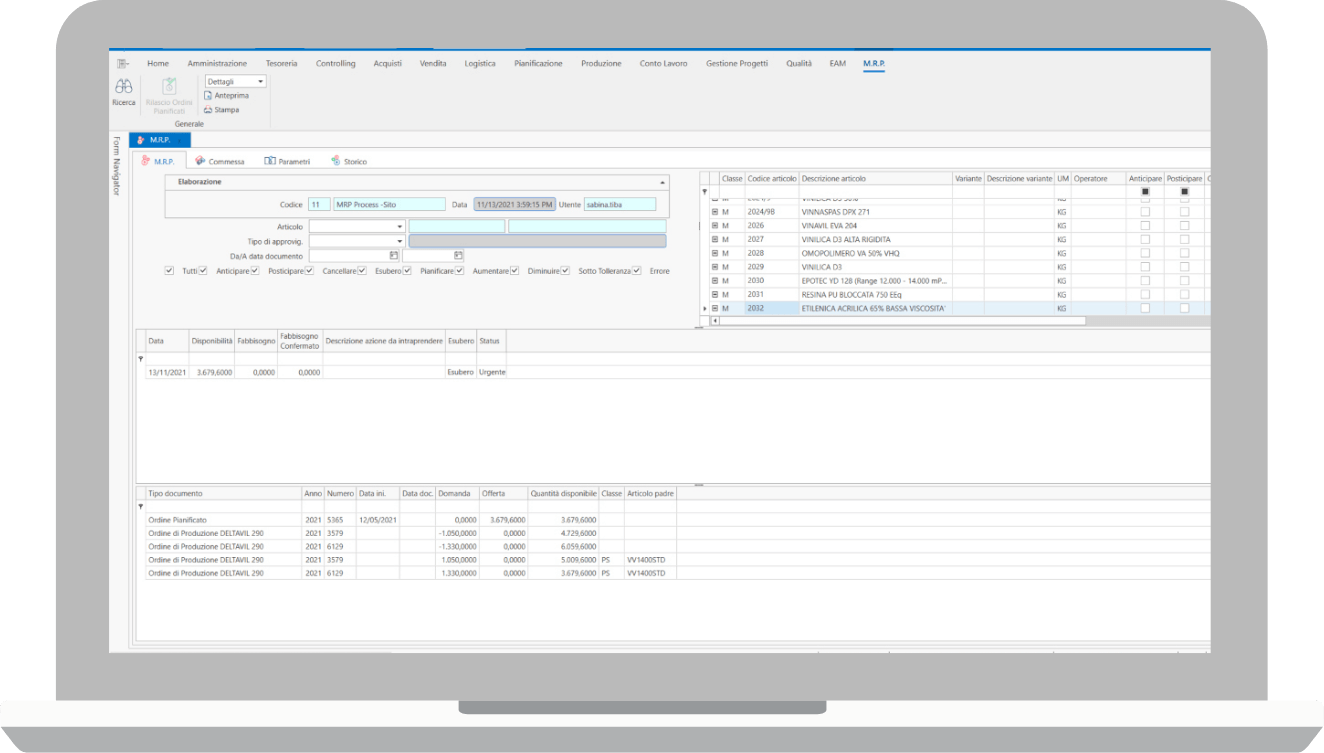

What to produce or purchase? How much? When? The MRP tells you

Only an MRP software can provide precise answers to these questions.

The integration of MRP software allows for the exact calculation of material/component requirements for each period by performing a multi-level explosion of the bill of materials, based on availability. This optimizes inventory management and shipping and production lead times.

The necessary actions to take, based on daily production variables, are automatically suggested.

Increase efficiency: the mantra of manufacturing companies

All details highlighted

The worksheet presents order details, displaying internal production phases, broken down by work center, start and end dates, planned times, and any production progress information, such as produced and discarded quantities. Knowing this information precisely and understanding which sheets are already in the department and which still need to be printed creates efficiency.

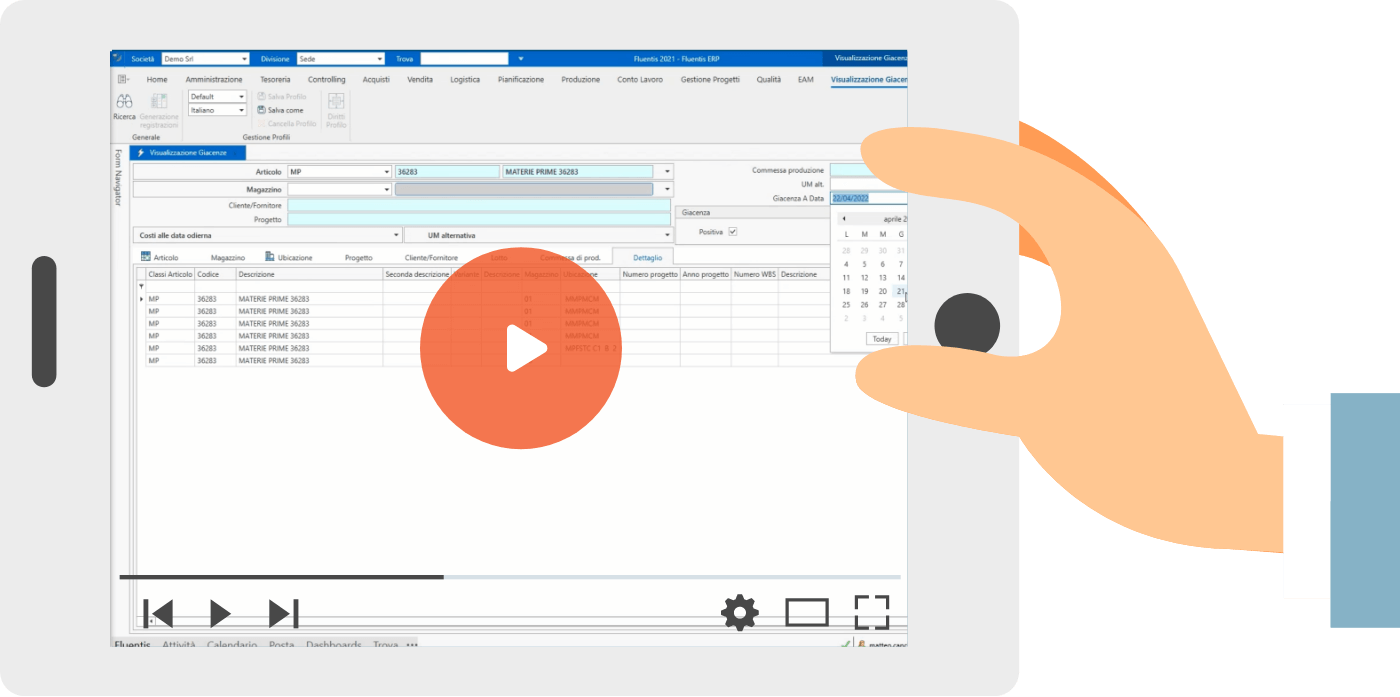

Easily retrieve materials

The material picking list is another support tool, allowing you to search for materials for the selected production order, creating picking lists that enable the automatic retrieval and movement of inventory, thanks to Fluentis’ WMS module. Having the right materials in the right department and at the right time creates efficiency.

Monitor phases in real-time

The production declaration and its progress status provide real-time updates on the production phases, ensuring smooth transitions to subsequent departments based on the sequence defined by the schedule. The MES also allows for continuous monitoring of the production job orders and production orders, including tracking profits and costs.

The advantages of an integrated MES

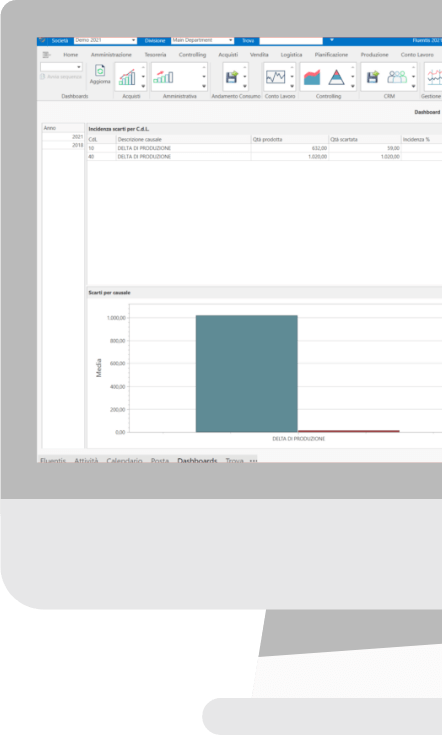

With Fluentis’ integrated MES, monitoring and optimizing production is guaranteed. The operator can report the quantities produced and manage scrap and waste.

Production reports can be entered manually or through customized dashboards that retrieve information directly from the machine, thanks to integration with Industry 4.0.

Materials, phases and sub-phases, equipment, and all related documentation are designed to make the execution of tasks as automated, organized, and smooth as possible.

The MES also allows continuous monitoring of production job orders and production orders, including tracking profits and costs.

In fact, by collecting real-time information, it is possible to obtain both job order costings and production order costings, comparing actual costs with projected costs, and viewing both gross and net margins directly linked to the sales order.

Learn More

MES Software : What They Are and Why They Are Essential in an ERP for Manufacturing Companies

MES systems are the key tool for the integrated management of data from production processes that significantly impact a company’s profitability.

The primary goal of an MES solution is to combine the optimization and flexibility of production and logistics processes with control over resource availability and product quality. MES software, through real-time application logic, allows for precise organization across all production departments and significantly contributes to performance improvement in the short term.

An MES solution ensures integration between different systems, structures machine automation through SCADA (Supervisory, Control, and Data Acquisition) processes, and manages the entire supply chain. In Fluentis ERP, the MES model has been implemented with a wide range of parameters. Thanks to this parameterization environment, the Fluentis MES algorithms represent a solution not only for general-purpose applications but also for specific productions in vertical markets.

The primary functions of an MES solution include:

Correct planning of production activities.

Movement and commitment of materials.

Allocation of internal/external resources.

Management of internal work orders and subcontracting.

Management of purchase planning.

Synchronization and coordination of processes.

Archiving, processing, and analysis of collected data.

Management of maintenance activities.

What our customers say about Fluentis

Fluentis ERP ha portato Manifattura Tubi Gomma ad un completo controllo del suo business, integrando nella stessa piattaforma tutte le funzioni aziendali.

Grazie all’implementazione di Fluentis ERP abbiamo ottenuto numerosi benefici. Le aree strategiche legate alla Supply Chain, alla Produzione, alla Raccolta dati sul campo sono state automatizzate e i relativi processi ottimizzati, consentendoci di utilizzare dati precisi e puntuali che ci danno l’opportunità di prendere decisioni tempestive e affidabili

- Mario Tonin, IT Manager

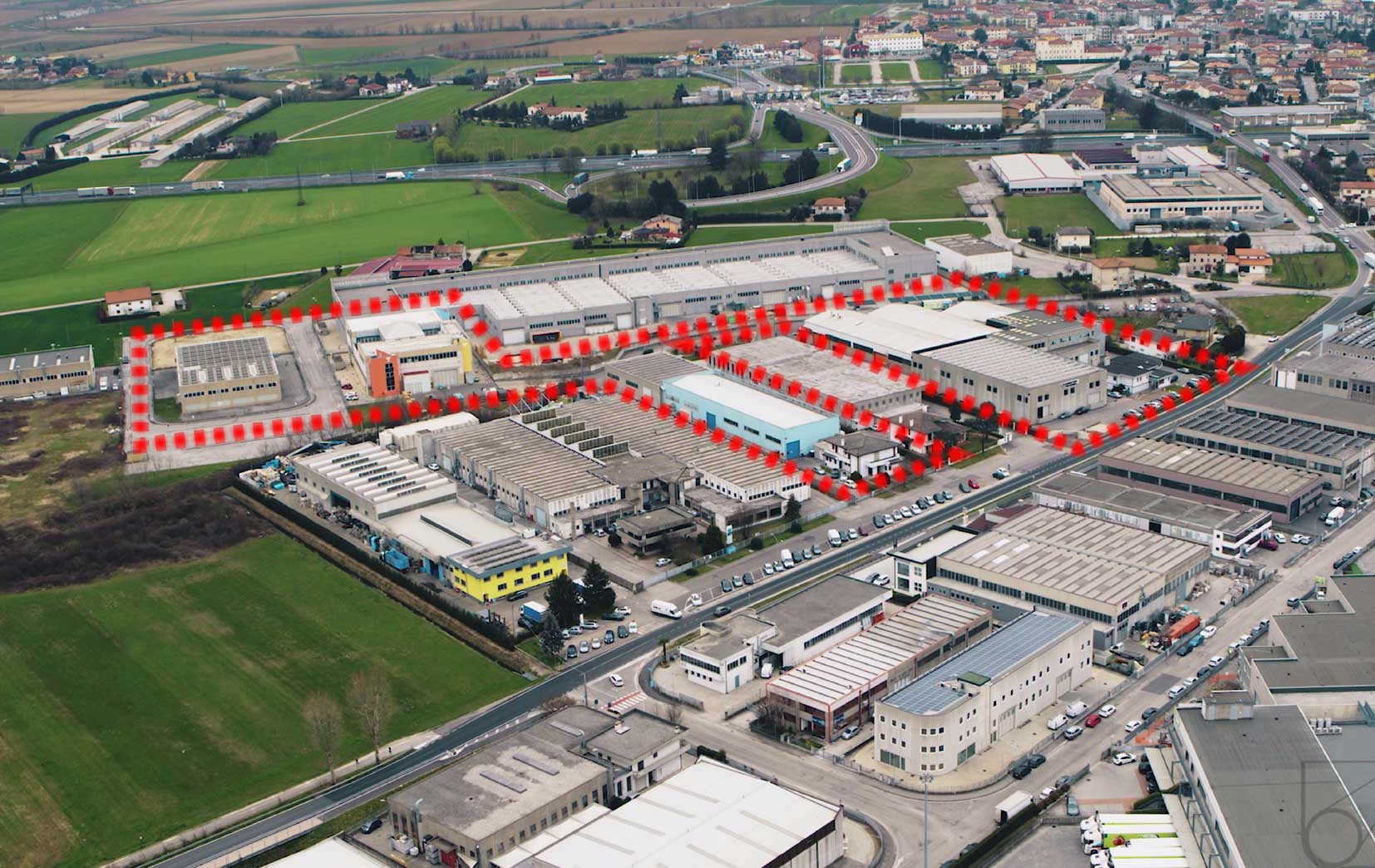

MTG SPA

Functional Modules

MRP

The MRP (Material Requirements Planning) calculates the material/component needs per period through a multi-level explosion of the bill of materials, helping the manager answer the following questions that only MRP software can resolve:

- What to produce or purchase?

- How much to produce and purchase?

- When to produce and purchase?

Features

- Analysis of materials and resources, management of advances, delays, surpluses, shortages, and proposals for eliminating existing proposals.

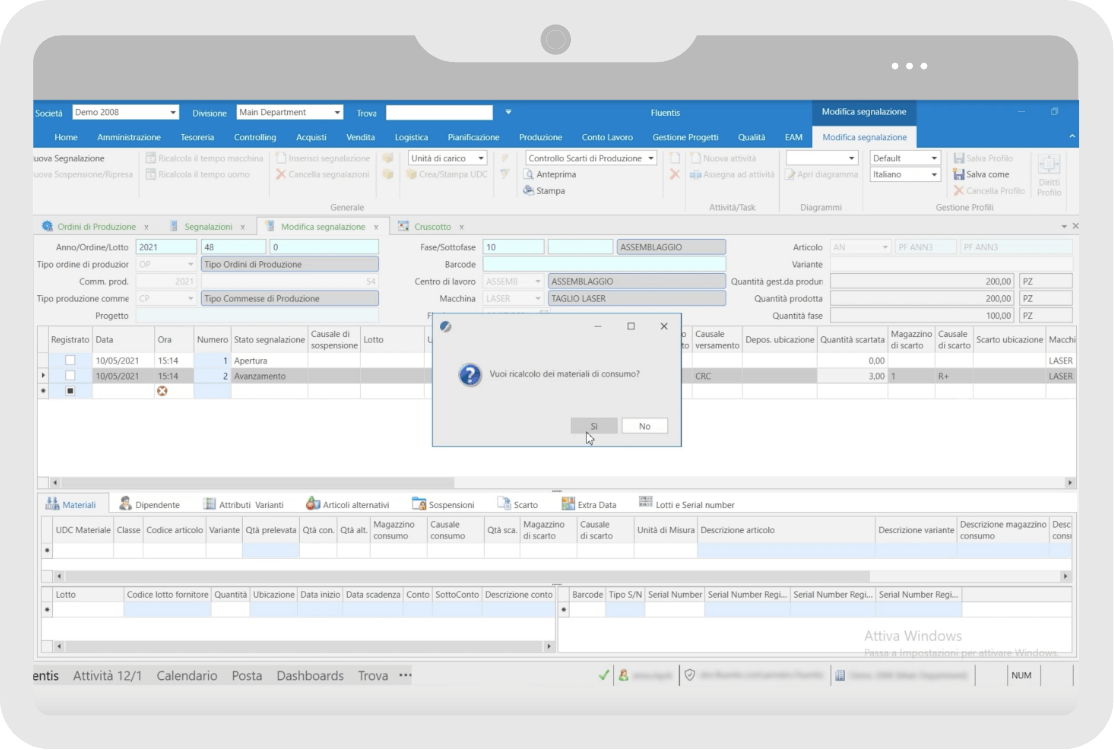

Production Declarations Management

This procedure allows you to declare the progress of work phases, documenting activities such as the start of operations, declarations of quantities produced, materials consumed, any scrap, time tracking, and the declaration of suspensions.

Through declarations, it is also possible to report the submission of alternative products and record the presence of each operator involved in the operations.

Features

- Manual entry or via MES

- Recalculation of machine and labor times based on manual variations

- Automatic recording of warehouse movements

- Work progress status

- Management of batches and serial numbers

- Costing of production orders

Costing

Through this procedure, it is possible to perform post-production checks on the actual time spent compared to the standard times set for a specific production order.

Production Costing

This is a particularly innovative procedure appreciated in production management systems. It allows shop floor operators to interact with the progress of production orders through a very user-friendly interface. With a touchscreen terminal, operators can easily report the progress of production phases.

This approach is much more suitable because operators are not required to use the traditional mouse and keyboard, making them faster and more flexible in interacting with the ERP system.

Discover how Fluentis ERP

can transform your business

15-day free trial | No automatic renewal | Instant access

Contact us for more information

Get in touch with us if you:

- Are a SME in Manufacturing, Distribution, or Services

- Need to streamline and digitalize your business processes

- Want to take advantage of the benefits of a native cloud solution

- Want to replace your non-integrated softwares with a unified ERP platform

+1 281 404 1726

Chat with us