Inventory & Warehouse Management

Save time, money, and resources with efficient warehouse management.

Fill out the form to request information

Warehouse Management System: A Key Element for Business Growth

Gain full control over every stage of the logistics process to enhance speed, reliability, and traceability

The Warehouse Management System (WMS) in Fluentis ERP encompasses all the features of a dedicated logistics module, designed to monitor and track the movement of goods in the warehouse and all items within and outside the company. This area integrates documents related to both the sales and procurement cycles, as well as internal movements linked to production transformation processes.

Implementing a Warehouse Management System that ensures proper logistics management is critical for improving productivity and efficiency. Key processes, such as inventory control, internal logistics operations, storage optimization, and goods flow management, depend on the system’s capabilities.

Effective Warehouse Management also provides tangible benefits in avoiding waste, unforeseen issues, and delays that could significantly impact the company’s bottom line.

Modules and FeaturesStrenghts

Management of variant-based items.

Management of alternative items.

Phase-out or depletion management.

Multi-plant, multi-warehouse, and production site management.

Batch (lot) management.

Serial number (or unit registration) management.

Management of Load Units (LU).

Location management.

Stock and availability tracking by warehouse, location, customer, supplier, item, variant, batch, project, or job order.

Packaging management.

Picking list management.

Delivery schedule management.

Management of traveling warehouses.

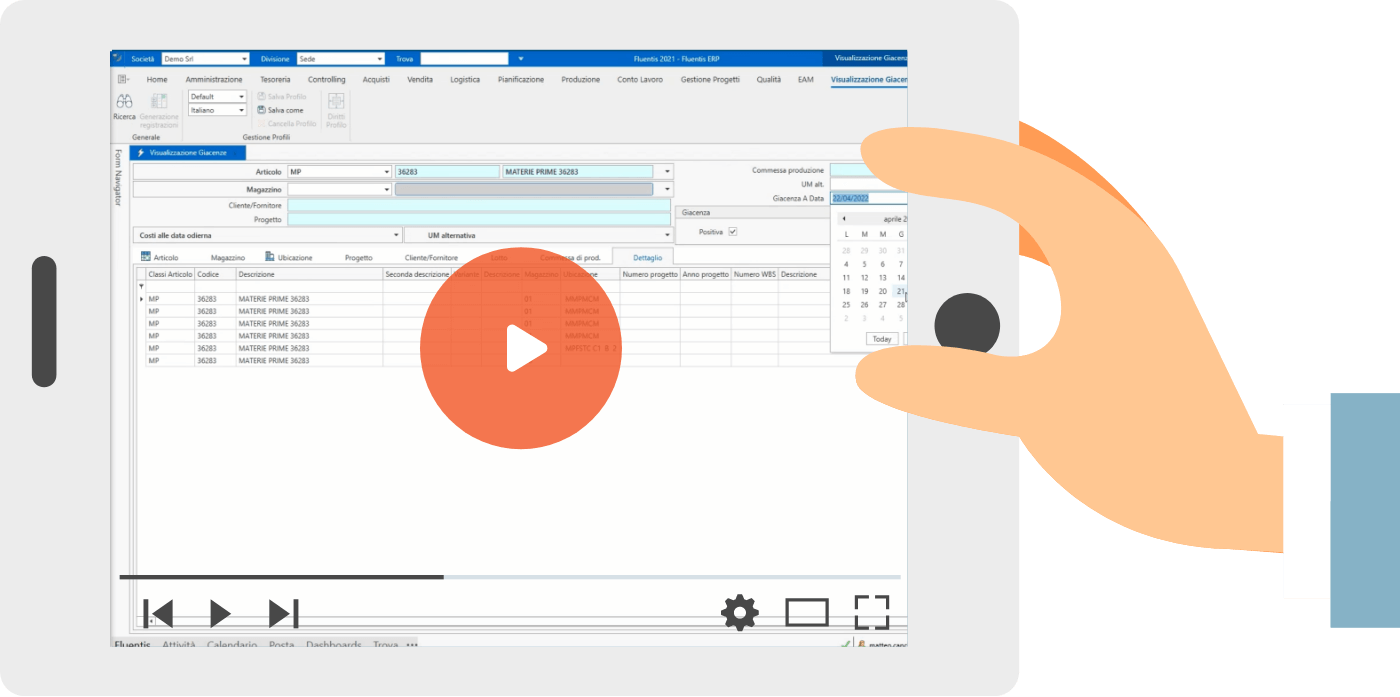

Inventory and Availability Always Under Control .

With Fluentis, you can monitor all warehouses, stock levels, and material movements in real-time. The system provides visibility into inventory levels based on multiple attributes, such as item, warehouse, location, batch, or serial number.

You can also review historical inventory levels, enabling you to track stock trends over time. Additionally, the availability analysis feature allows for parameterized queries using various filters, such as date or commitment type, to ensure a comprehensive view of your inventory.

The system also supports feasibility checks for products by displaying the availability of components derived from the first-level explosion of the bill of materials (BOM).

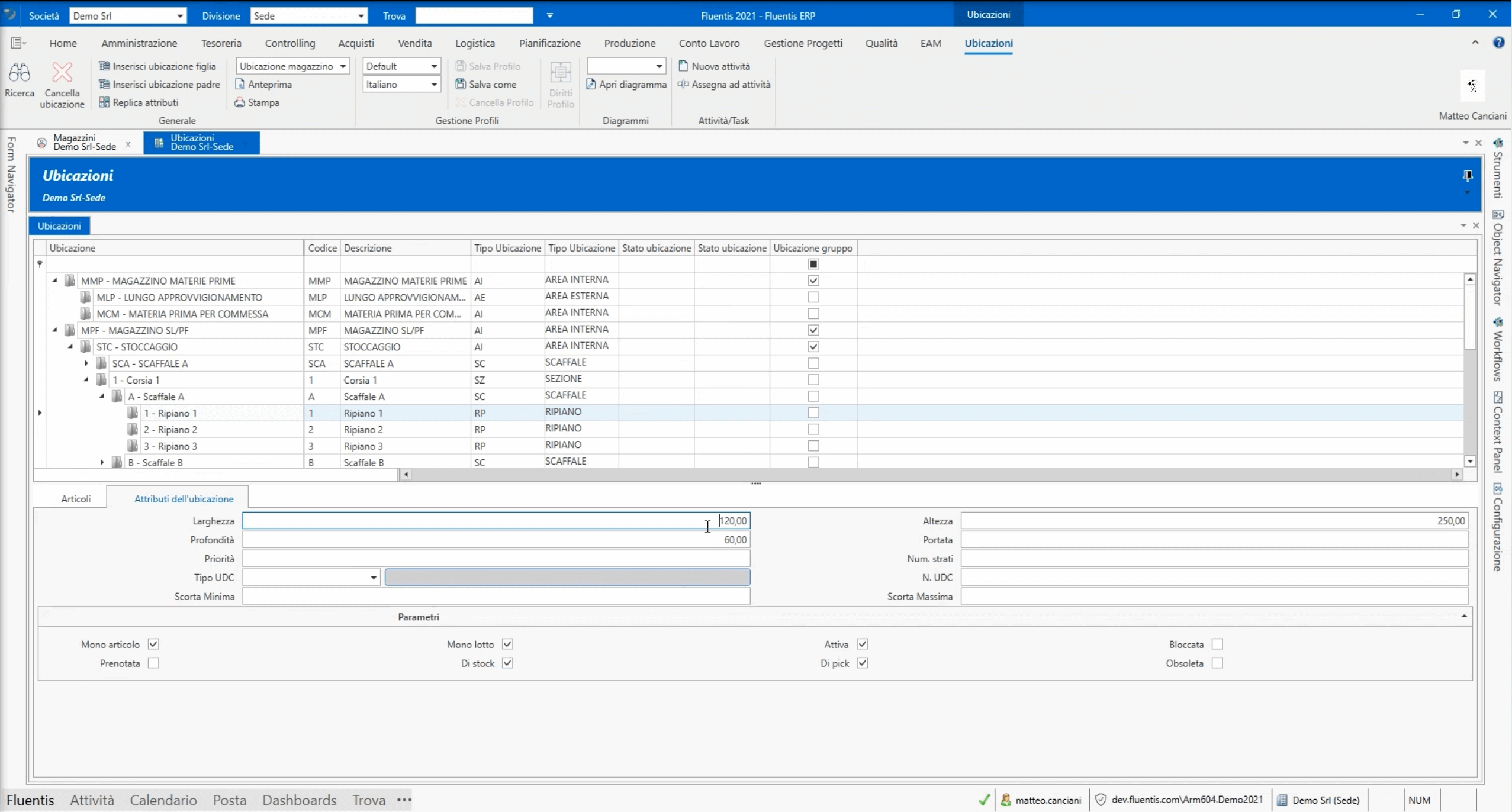

Location Coding Made Simple

Fluentis allows you to create an unlimited number of warehouses, whether physical or logical, and assign locations to them. Locations can be quickly and easily set up using a tree structure that supports infinite levels of detail.

Each location can be customized with attributes such as designations for stock or pick areas, along with dimensions and load capacity. This setup enables controls that provide operators with quick suggestions for the optimal location to store goods.

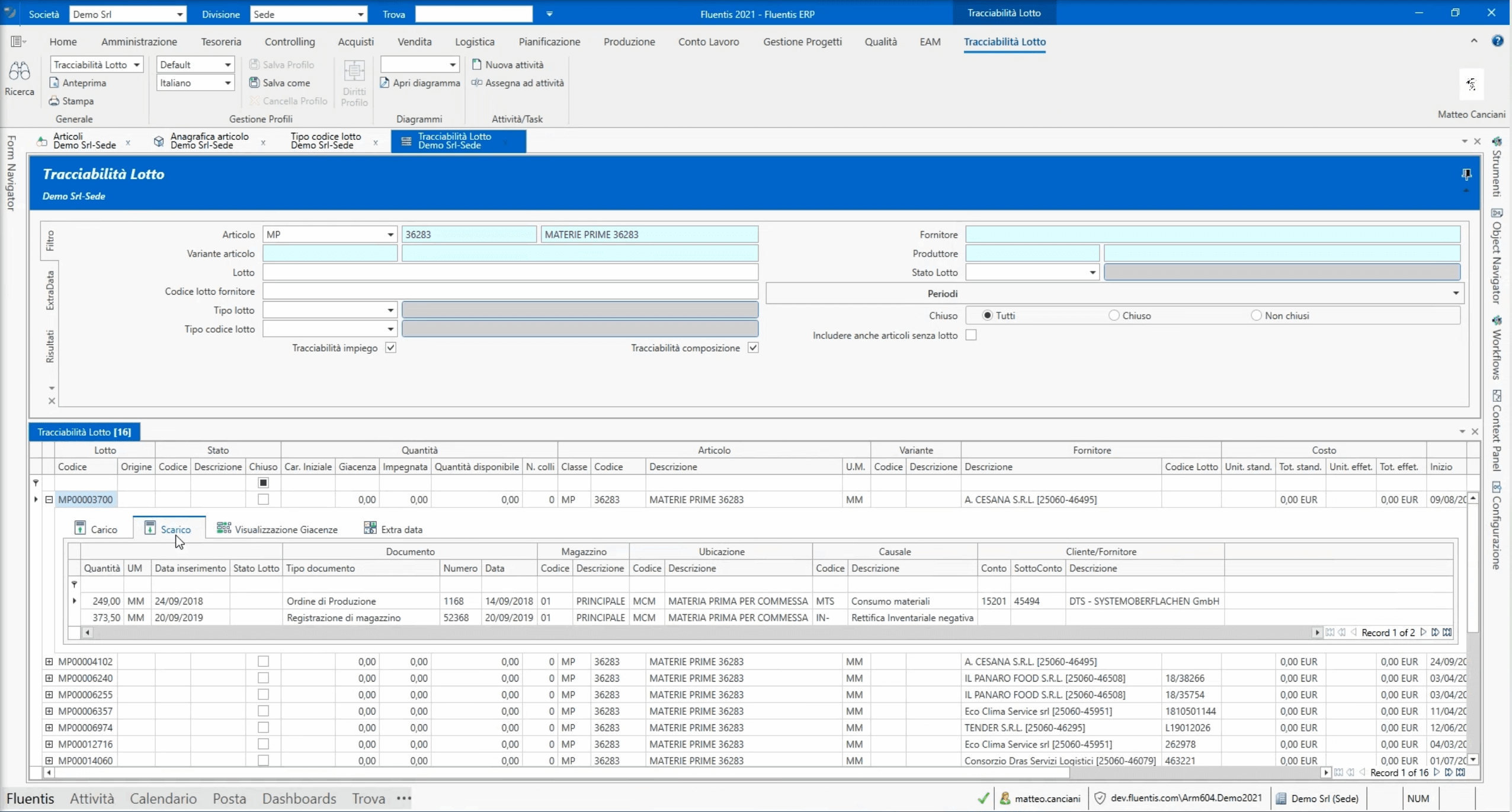

Batch and Serial Number Traceability

Based on warehouse movements associated with batch and serial number information, Fluentis establishes a connection that enables both forward and backward traceability of batches.

Gain an Edge with the

Integrated WMS .

Maximum Efficiency Through Mobile Integration

The Warehouse Management System (WMS) in Fluentis streamlines operations across Purchasing, Logistics, Picking, UDC (Unit Load), and Sales, all accessible via mobile devices for unparalleled flexibility and efficiency.

- Purchasing: Create Goods Receipt Notes directly from Purchase Orders, automatically generating corresponding warehouse records.

- Logistics: Manage warehouse movements, view inventory levels, and generate inventory count lists.

- Picking: Facilitate the creation and fulfillment of picking orders.

- UDC (Unit Load): Create and manage UDCs, handle their loading and movement, and complete deliveries from picking orders.

- Sales: Generate Goods Delivery Notes directly from Customer Orders, with automatic creation of related warehouse entries.

Optimize every step of your supply chain with a mobile-enabled WMS that keeps your operations efficient and connected.

Learn More

What our customers say about Fluentis

Grazie all’implementazione di Fluentis ERP abbiamo ottenuto numerosi benefici. Le aree strategiche legate alla Supply Chain, alla Produzione e al Controllo di Gestione sono state automatizzate e i relativi processi snelliti ed ottimizzati. Questo ci consente di basare la nostra gestione su dati accurati e certificati in tempo reale. Il risultato è una rapidità nella gestione delle richieste dei clienti, e una maggiore tempestività e consapevolezza nelle decisioni da intraprendere

- Dott.ssa Maria De Marchi, Owner

FAC Srl

Warehouses and Locations

Maintain real-time control of stock levels, availability, and inventory movements with Fluentis ERP’s detailed warehouse management capabilities. The system allows for the creation of multiple physical or logical warehouses and their corresponding locations, providing precise tracking and management.

A hierarchical location structure ensures a clear view of warehouse divisions, with customizable levels of detail to suit any business’s specific needs.

Features

- Transaction Recording and Posting: Simplify warehouse movements with accurate record-keeping and seamless accounting integration.

- Customer/Supplier-Based Management: Track inventory at the client or supplier level for better transparency.

- Inventory Visualization: Access detailed stock views by warehouse, location, client/supplier, lot, and serial number.

- Quick Entry of Records: Use the streamlined inventory transaction generation feature to record movements efficiently.

- Tree Structure Creation: Easily design a simple and intuitive hierarchical structure for locations.

- Item Location Mapping: Visualize where each item is stored.

- Location Attributes: Define dimensions, capacity, priorities, and minimum/maximum stock levels for each location.

- UDC Compatibility: Specify the type and number of Unit Load Containers (UDCs) available for each location.

Lots and Serial Numbers

Enhance inventory supervision and control with Fluentis ERP’s Lot and Serial Number Management. This functionality ensures effective monitoring and organization of stock levels, movements, item commitments, and comprehensive traceability for product lots or individual pieces.

When enabled, the system automatically generates and proposes codes during item transactions across various documents. Additionally, you can define and assign statuses to lots, providing a clear view of product conformity.

Fluentis ERP supports flexible picking strategies, including LIFO, FIFO, FEFO, or manual selection, ensuring inventory accuracy and efficiency.

Features

- Complete Lot and Serial Number Traceability

- Advanced Picking Managemen including: LIFO (Last In, First Out), FIFO (First In, First Out), FEFO (First Expired, First Out) and Manual picking.

Unit of Cargo (UDC)

The implementation of Unit of Cargo (UDC) management allows for the aggregation of items during loading and movement. UDCs facilitate the identification of batches of goods stored in the warehouse, and their use extends across multiple areas of Fluentis functionality. They can be utilized in goods receipt, warehouse management, production, subcontracting, and sales.

Features

- Creation and movement of UDCs

- UDC picking list creation

- UDC transfer list creation

- Packing list creation

Picking List

To manage transfers or shipments, Fluentis ERP offers the Picking List module, directly integrated with the WMS (Warehouse Management System). This feature enables warehouse staff to pick goods from inventory and make them available for production departments and shipping areas.

For production-related picking, the outcome will be the availability of products in the Work in Progress (WIP) area. For shipments, the picking process is followed by the automatic generation of the Delivery Note (DDT) or Accompanying Invoice, with real-time and automated warehouse movements.

Features

- Create picking lists from customer order fulfillment, production orders, loading plans, or manually

- Automatic generation of DDT and invoices directly from the picking list

- Warehouse movements for picking lists are handled automatically and in real time

Loading Plans

Fluentis ERP features the Loading Plans module, designed to simplify the preparation of shipments to customers. This interface provides clear visibility of customer orders, organized by delivery date and the available stock of items in the warehouse.

The function allows for order fulfillment using a picking list, followed by the automatic creation of a Delivery Note (DDT) or Invoice. The process also includes information on the weight and volume of the goods to be shipped, linked to the dedicated vehicle for the shipment. This ensures the user can always monitor if the weight and volume exceed available capacity.

Features

- Analyze customer order items based on order quantity, stock, availability, and commitments in open orders

- Create picking lists and pick-up lists

- Automatic generation of DDT and invoices directly from the loading plan

- Create delivery route models

Stock Replenishment and Reorder Point

To manage inventory levels effectively, Fluentis ERP offers a feature that calculates stock shortages over time. At the article master level, the system allows for the entry of procurement data, such as Minimum Stock, Maximum Stock, Reorder Point, Reorder Lead Time, with details available for each individual warehouse.

Based on the entered information and a procedure that calculates average daily consumption, Fluentis ERP provides the required quantity to replenish in order to avoid stockouts by the specified date. Additionally, the module automatically generates procurement documents (Purchase Requests) based on the identified needs.

Features

- Stockout management

- Reorder point management

- Automatic creation of purchase requests (RDA)

Inventory Lists and Cycle Counting

Leveraging the features in the inventory module, Fluentis ERP enables quick and efficient creation and population of inventory lists by searching for moved items. The system retrieves not only the items but also details related to lots, locations, and inventory levels. The user’s task is simply to verify and record the physical stock of the items.

Based on this information, adjustment movements are automatically generated to align the stock levels. The cycle counting functionality allows specific warehouse areas (e.g., locations) to be locked and isolated for rapid verification of inventory, adjustment processing, and reactivation of the area once the operation is complete. This significantly reduces the complexity and cost of physical inventory management.

Features

- Creation of inventories

- Generation of inventory lists by warehouse/operator

- Reconciliation of logical and physical stock discrepancies

- Warehouse closure history

- Quantity-based and value-based inventory

- Inventory valuation

Packing List

A document used for shipments to non-EU countries, the Packing List is highly beneficial for all types of shipping. The Packing List must specify the packages and the items contained within them, including details such as net and gross weight, width, height, volume, and nature of the goods.

When integrated with the WMS module, the Packing List can be generated even more easily by utilizing the Load Units (packages) already available in the system.

Features

- Traceability of items within Load Units (UDC)

- Management of Packing Lists for Lots / Serial Numbers

- Automatic generation of DDT from Packing List

- Management of weights, volumes, and dimensions

Discover how Fluentis ERP

can transform your business

15-day free trial | No automatic renewal | Instant access

Contact us for more information

Get in touch with us if you:

- Are a SME in Manufacturing, Distribution, or Services

- Need to streamline and digitalize your business processes

- Want to take advantage of the benefits of a native cloud solution

- Want to replace your non-integrated softwares with a unified ERP platform

+1 281 404 1726

Chat with us