Fluentis ERP Features for COOs

Operations Management (COO)

Essential KPIs for the COO

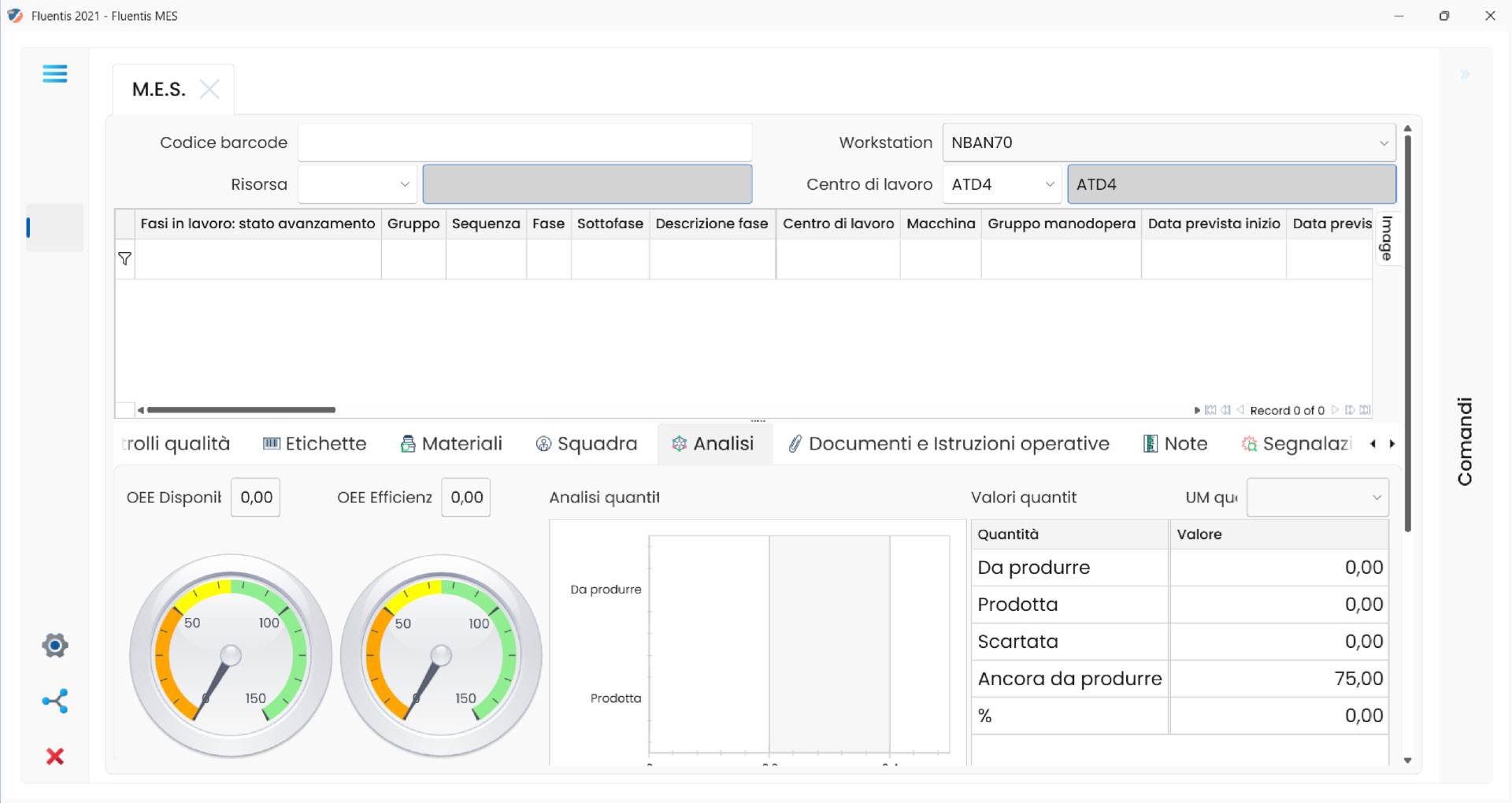

OEE - Overall Equipment Effectiveness

Throughput - Analyzes production volume and capacity utilization across work centers

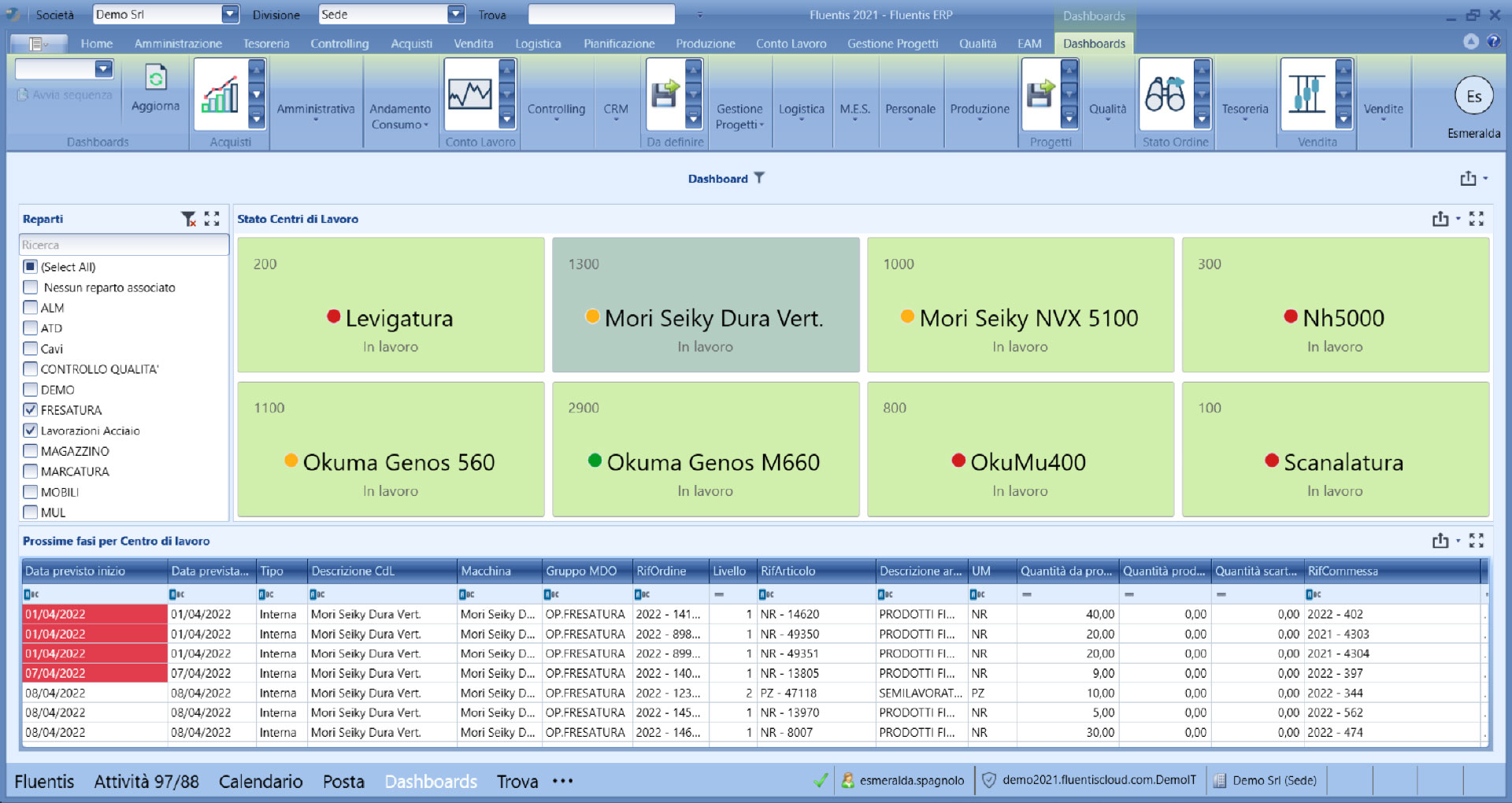

Work Center Status - Monitors machine downtime, identifying causes of inefficiency and the impact of various types of downtime

Engineering Performance - Evaluates the technical department's activities, supported by project management tools and Work Breakdown Structure (WBS) analysis

Cost of Production and Budget Adherence - Compares actual production costs and project expenditures against budgeted figures to assess financial performance

Availability - Measures the ratio of actual operational hours of equipment to total potential operating hours

Efficiency - Analyzes the difference between estimated production time and actual time taken to produce items

Quality Metrics - Assesses the proportion of approved products relative to total production volume

All the Tools to Execute and Track Business Strategy

With Fluentis ERP, COOs gain real-time visibility across the entire organization, enabling quick, informed decisions to align daily operations with strategic goals.

As Operations Leaders, COOs oversee every step in core business processes. Fluentis ERP supports them in turning strategy into action, allowing constant tracking of productivity, costs, and product or service quality.

The Role of the Chief Operating Officer (COO)

The COO oversees all project and operational activities required to deliver the final product or service to customers.

The COO’s mission is to bring the business plan to life, making activities and processes more functional and competitive.

This role demands high expertise and professionalism, as the COO must continuously bridge strategy and execution to ensure strong results.

How Fluentis ERP Empowers Operations Leaders

Optimized Processes

Redesign and automate production workflows with fully customizable tools.

Logistics Operations

Monitor inbound and outbound logistics in real time with Fluentis’ native Warehouse Management System (WMS), enabling real-time movement tracking through barcode scanning.

Quality Control at Every Step

With Fluentis’ integrated Quality module, you can continuously monitor complaints and non-conformities, ensuring full traceability of every item at each stage—from goods receipt and purchase invoice to all phases of production, returns from subcontractors, and every warehouse movement.

Production and Procurement Planning

Fluentis’ Master Production Schedule (MPS) lets you manage different production methods—like make-to-stock and make-to-order—easily through simple setup.

You can plan production based on customer orders and safety stock while considering your sales forecasts. The Fluentis Controlling module helps optimize logistics by tracking inventory needs.

The Materials Requirements Planning (MRP) module improves resource management with features for minimum stock levels, reorder points, and lead times. An advanced messaging system ensures efficient material replenishment.

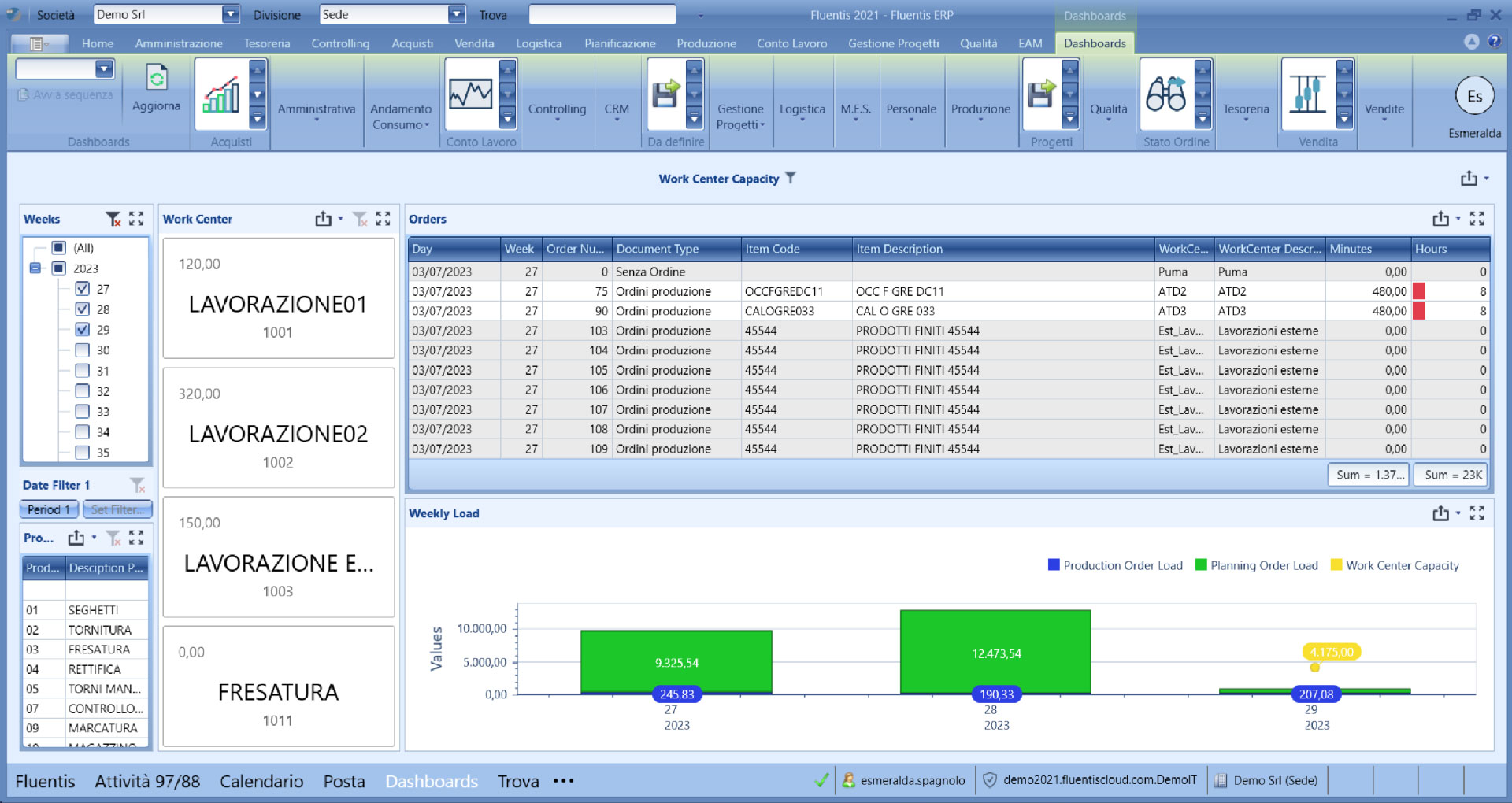

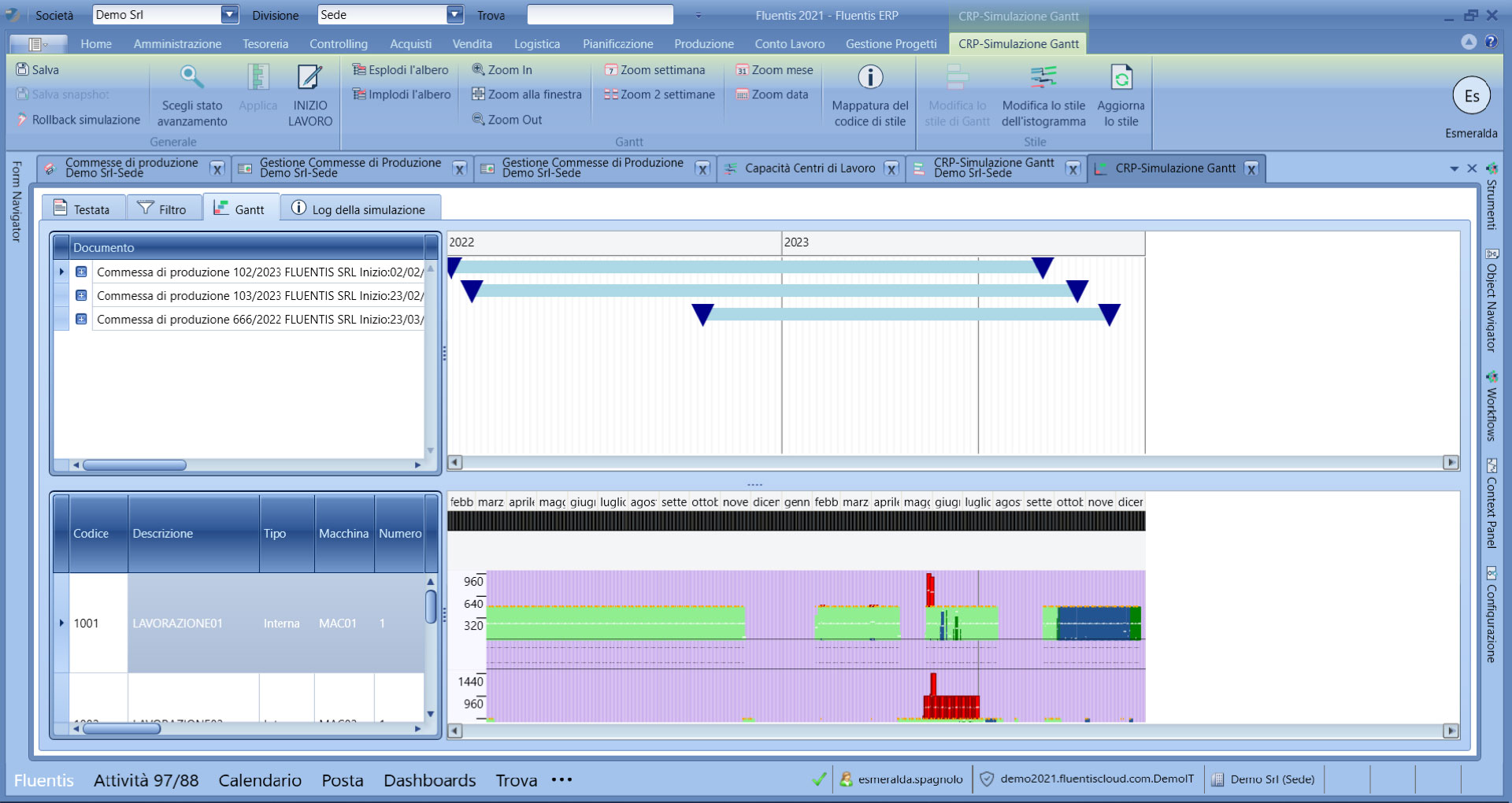

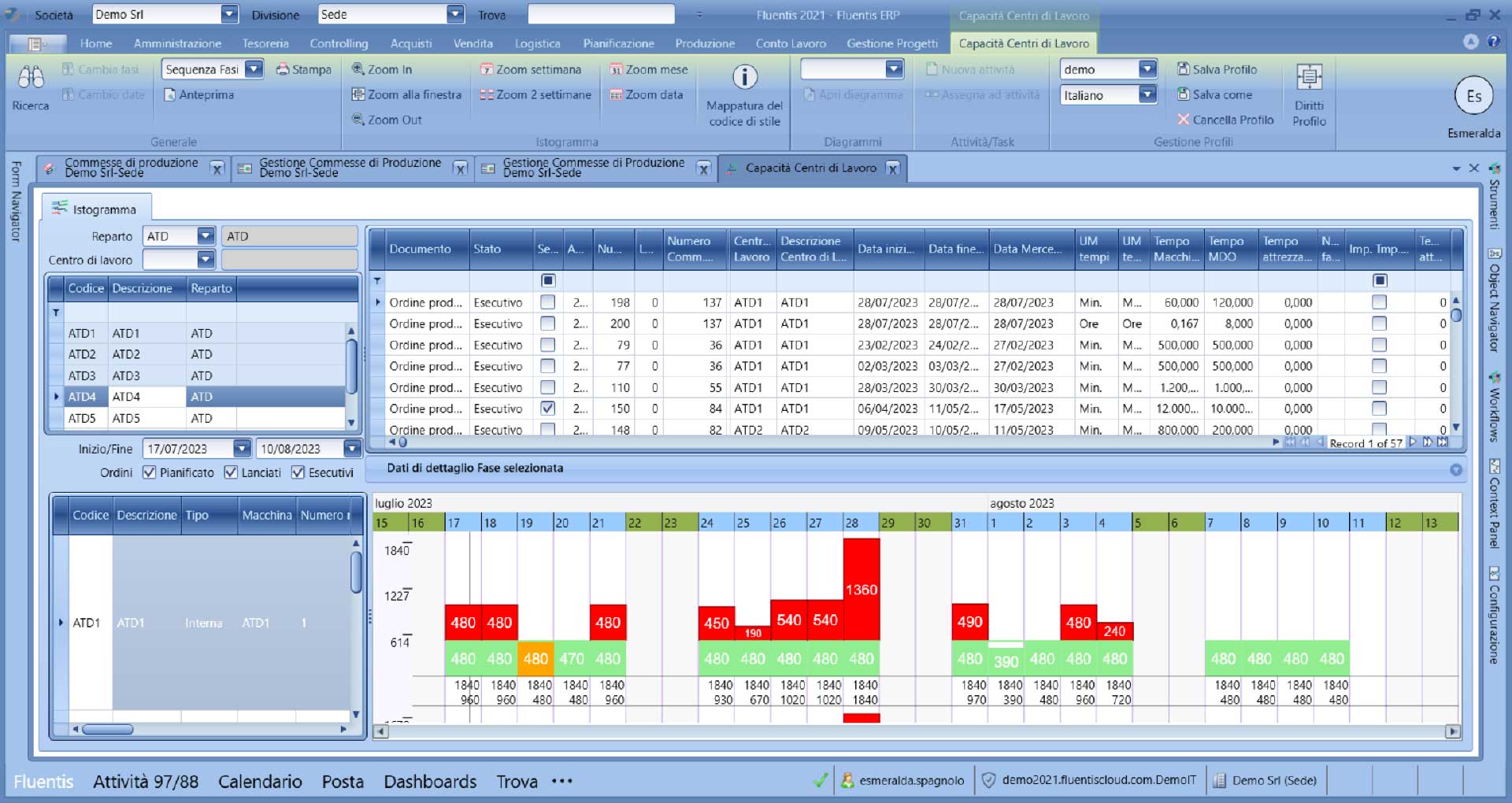

Infinite and Finite Capacity Scheduling

With Fluentis, you can plan production resources and materials using both infinite and finite capacity scheduling. The system optimizes workloads at work centers, with Capacity Requirements Planning (CRP) analysis presented visually through Gantt charts.

You can simulate planned orders for production, subcontracting, and purchasing before making them final.

Scheduling priorities, such as customer urgency, delivery dates, and critical work centers, support finite capacity analysis. By defining a maximum daily capacity, the system distributes workloads across resources and days to avoid daily overloads while adhering to configured priorities and constraints.

Real-Time Operational Control

Fluentis’ native Manufacturing Execution System (MES) delivers real-time data on operator performance, with the option to gather information directly from machines in line with Industry 4.0 standards.

By tracking production data, you can perform comparative analyses against planned standards to evaluate time and cost efficiency.

Keep a close eye on operational effectiveness with continuous monitoring of factory activities and Overall Equipment Effectiveness (OEE) analysis.

Discover how Fluentis ERP

can transform your business

15-day free trial | No automatic renewal | Instant access

Contact us for more information

Get in touch with us if you:

- Are a SME in Manufacturing, Distribution, or Services

- Need to streamline and digitalize your business processes

- Want to take advantage of the benefits of a native cloud solution

- Want to replace your non-integrated softwares with a unified ERP platform

+1 281 404 1726

Chat with us