Integrated DDMRP in ERP:

Functionalities and Features

Fill out the form to request information

Manage the Supply Chain based on demand with DDMRP

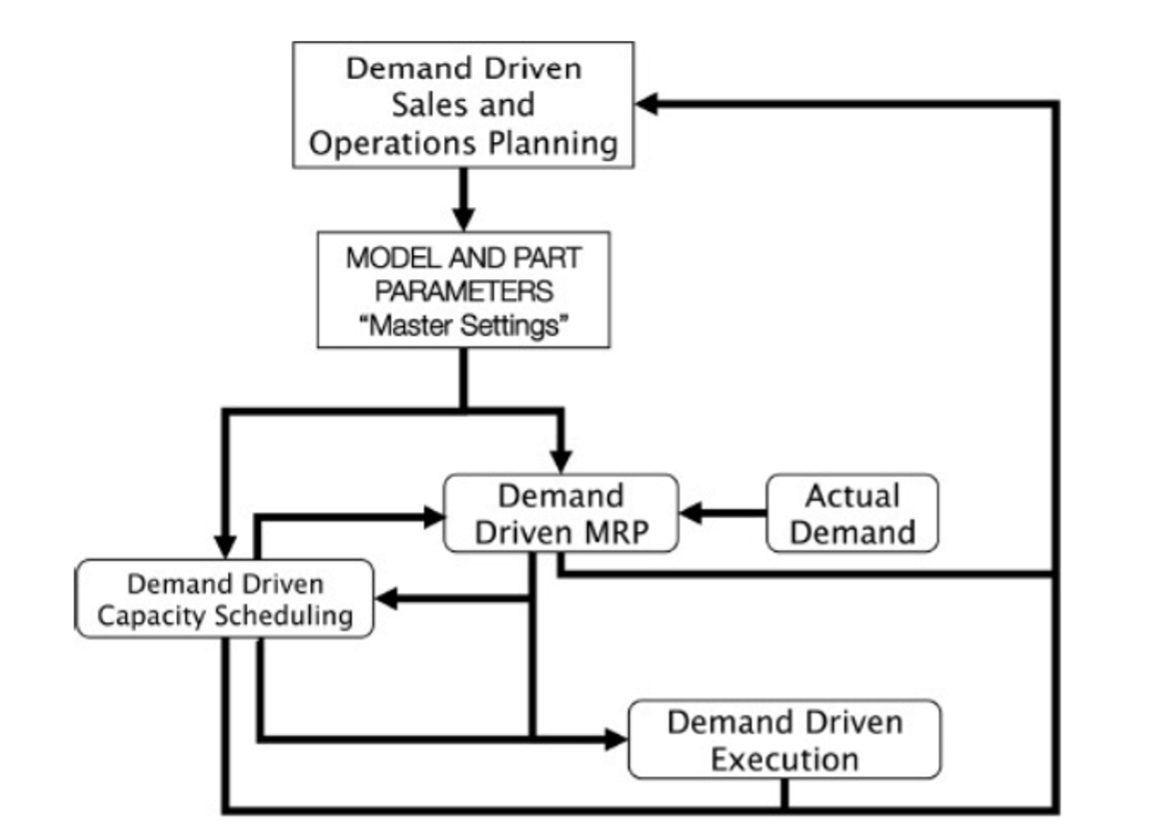

The acronym DDMRP stands for the cornerstone of a planning methodology that applies to an entire Supply Chain, known as Demand Driven. DDMRP was created to ensure the availability of goods at the expected times and locations, even in the presence of unpredictable and highly variable demand, and with not very reliable supplies.

Traditional MRP systems have proven ineffective in guaranteeing performance in terms of customer service levels and low operating costs when operating in a chaotic and uncertain environment.

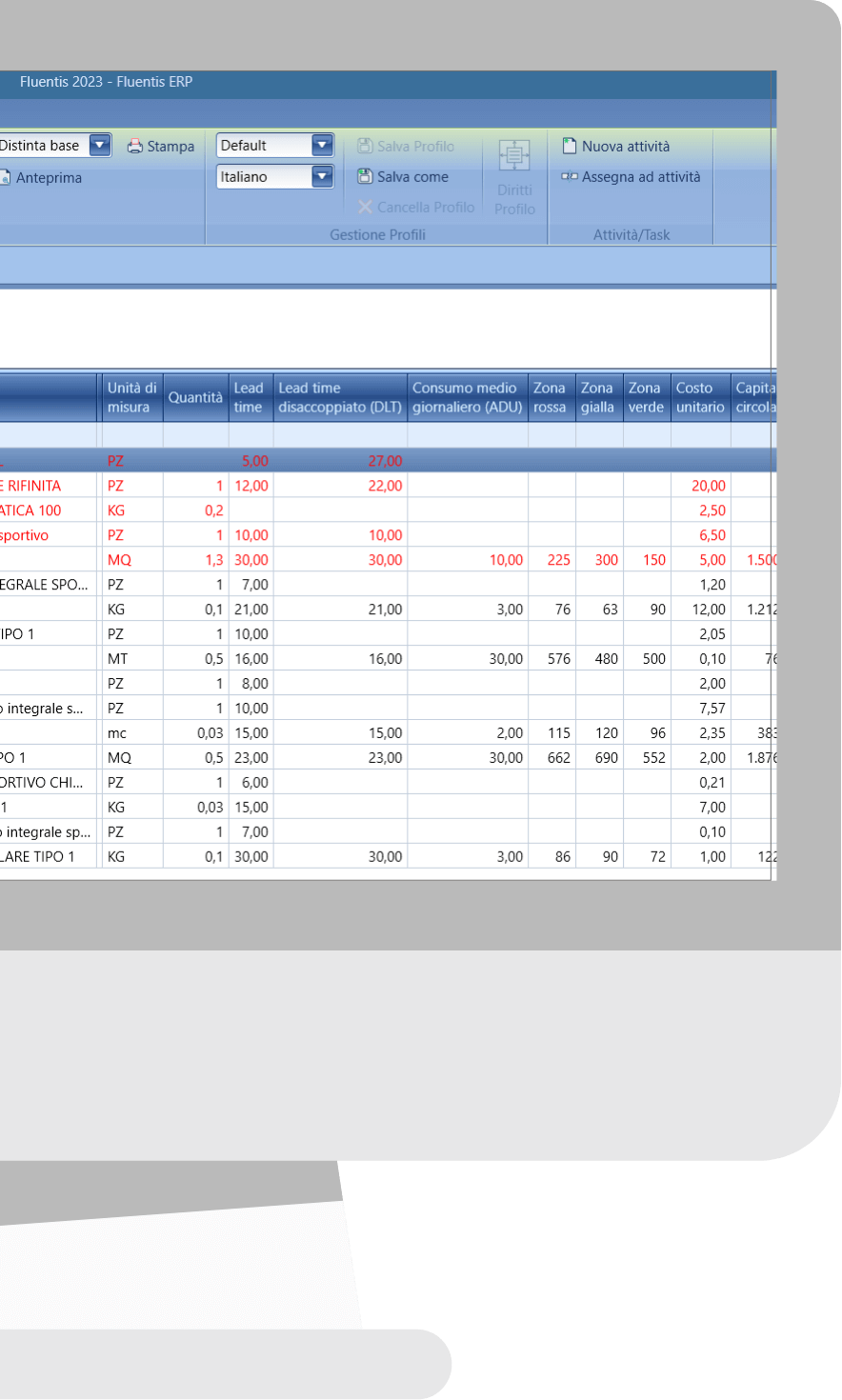

The Fluentis DDMRP solution is natively integrated with Fluentis ERP, eliminating the need to create data exchange interfaces (with all the associated problems) typical of vertical solutions on the market.

In addition, Fluentis DDMRP provides tools that include unique and proprietary know-how to support customers in the strategic analysis phase of selecting inventory elements and real-time analysis of critical issues and system status.

The Origins of DDMRP

DDMRP is a methodology that evolved from MRP and began to spread at the beginning of the second decade of the 2000s due to the inadequacy of conventional planning methods to operate effectively in a much more complex and dynamic scenario than when MRP was conceived in the 1960s.

The progress in communication technologies (the internet) has made the world much more interconnected, making it easier to search for goods and services and creating business opportunities even across very distant geographic areas. Today, it is common to have suppliers in other continents (such as China, India, Korea, etc.), and the same is true for customers. E-commerce has completely transformed supply chains, especially in the last 20 years. The context in which companies operate today has become much more complex, variable, and requires much faster response times compared to the times when MRP was conceived.

In recent decades, MRP has shown all its limitations in managing the complexity of modern supply chains, which is why there was a need to develop a new tool to overcome these limitations.

The main limitation of MRP is its failure to take into account the complexity and volatility of today’s market, characterized by products with increasingly shorter lifecycles and increasingly demanding customization requirements. The supply chain is also more variable and complex, with a significant increase in the number of actors involved.

The use of inadequate tools and methodologies in today’s environment leads to problems such as:

Low customer service levels;

High inventory levels

High operating costs.

All of these problems inevitably lead to a reduction in corporate profitability and require greater financial commitment in terms of working capital invested at the same sales volume.

DDMRP: For Whom and Why

The Demand Driven methodology is particularly suitable for companies that need to anticipate market demand by making purchases or producing semi-finished goods based on forecasts to reduce customer lead times to an acceptable level.

In this type of context, one of the main problems is being able to make reliable sales forecasts, which is extremely challenging and results in inherent imprecision, either leading to lost business due to underestimating demand or excessive inventory due to overestimation.

In the Demand Driven logic, sales forecasts are not used, and the system is based solely on actual demand (hence “demand-driven”), automatically adjusting to it.

The Demand Driven method uses strategic stock of certain elements of product structures, identified based on rigorous analysis of company data.

These stocks allow a high degree of “insensitivity” to internal and external variability, minimizing the negative effects of all unforeseen events, thus reducing variability (a goal of lean six-sigma methodology).

The level of these stocks is continuously adjusted based on demand trends and any known future events (promotions, seasonality, etc.) following a “pull” logic.

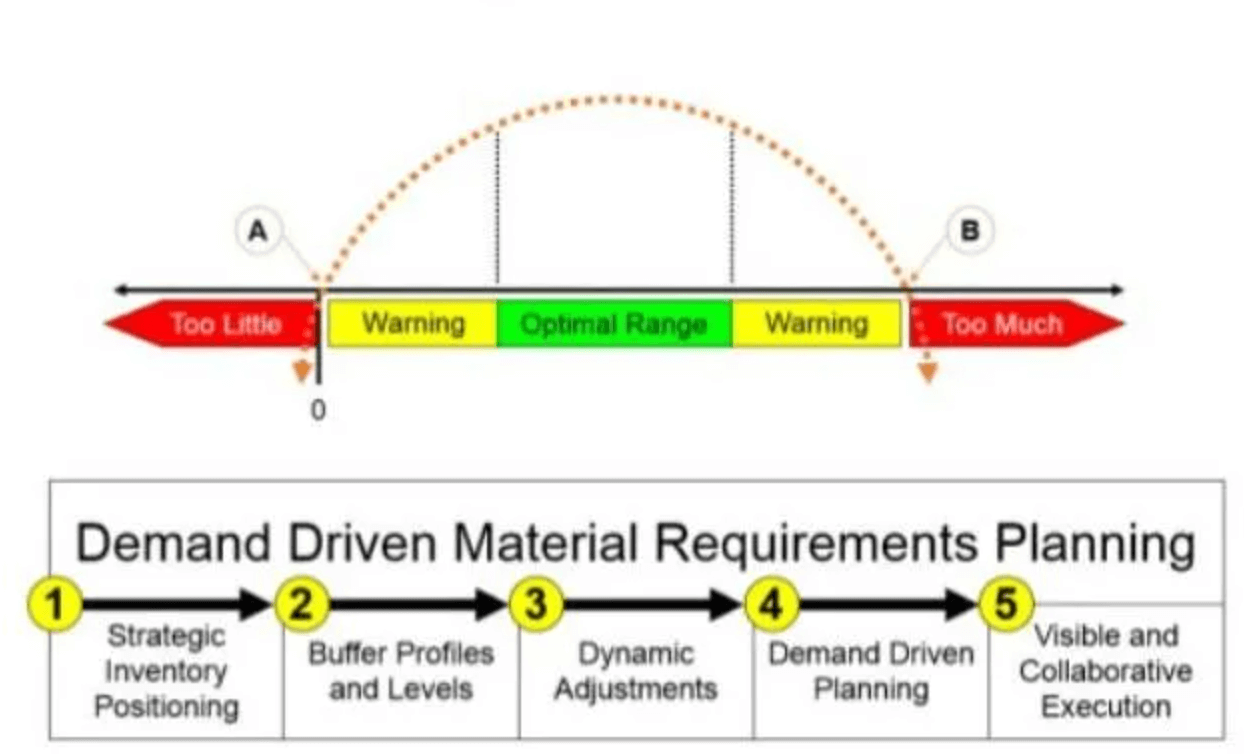

This methodology is very simple and intuitive, relying on a wide use of three colors to make the state of affairs immediately evident (Red for “critical situation,” Yellow for “moderate risk,” Green for “no danger”).

It also significantly increases visibility</strong, the ability to identify and communicate (internally and externally) critical elements on which to focus attention and their priority level.

Production planning is also greatly simplified and stabilized, reducing costs and increasing quality.

The advantages brought by DDMRP

The typical advantages offered by this methodology include:

Reduced lead times (=> increased revenue potential)

Improved service levels (better customer satisfaction => increased revenue potential)

Reduced inventory levels (lower capital requirements and lower operating costs)

Reduced operating costs due to unforeseen events (reduced rush shipments, rework, overtime, etc.)

Improved visibility (=> faster response times)

Reduced variability (=> lower costs and better quality)

Increased decision speed and merchandise flow (=> improved profitability and liquidity).

These last three points represent the goal for excellent supply chain management as recommended by the ASCM (Association for Supply Chain Management), the most important and accredited organization in terms of operations know-how.

Increase in service levels

between 13% and 54%

Reduction in lead times

between 22% and 85%

Inventory reduction

between 31% and 60%

To better understand the level of improvement that can be expected from the introduction of the Demand Driven methodology, we present the results of a survey conducted by an independent consulting company on a large sample of companies in various business sectors that have adopted it.

Today, many companies of various sizes use DDMRP, including well-known names such as Coca Cola, Shell, Michelin, Nestlé, Philips, Legrand.

Discover how Fluentis ERP

can transform your business

15-day free trial | No automatic renewal | Instant access

Contact us for more information

Get in touch with us if you:

- Are a SMB in Manufacturing, Distribution, or Services

- Need to streamline and digitalize your business processes

- Want to take advantage of the benefits of a native cloud solution

- Want to replace your non-integrated softwares with a unified ERP platform

+1 281 404 1726

Chat with us