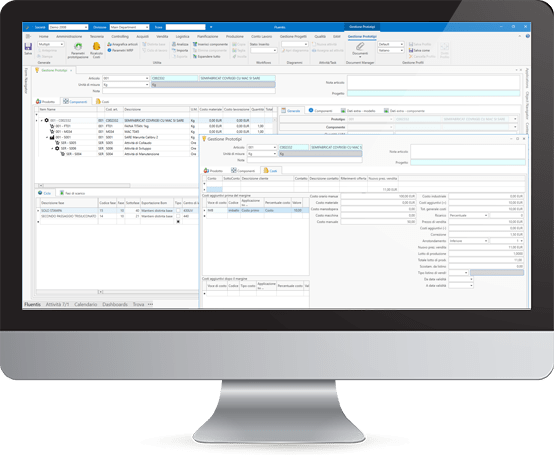

The definition of the Prototype guarantees the order margin

For companies that work by order, the product is never characterized by standard specifications, but almost always by unique construction requiring careful analysis of all components. Normally, these companies begin production only upon receipt of the customer’s order. In this scenario, the user must produce a cost estimate to determine the production times and to proceed with the commercial offer. And then, of course, organize the actual production of the goods.

The need for management software that includes a Prototype module often arises when the product being negotiated has specially customized characteristics. A need exists, therefore, to identify all the components of material cost, processing cost and indirect costs to be assigned to this order, in order to build an overall cost. The real sale price is defined with a suitable MarkUp to this overall cost. The company then proceeds with awareness of the realization of what the customer requests and the assuredness of having guaranteed a predefined margin for the whole operation.