Fluentis ERP software allows manufacturers and industrial organizations to manage production and all its operational aspects, including complex budgeting, final costs, materials and activities.

Fluentis algorithms allow you to manage all internal and external business processes of the entire product life cycle: from budgeting to design, to procurement of materials and production resources, to internal and/or subcontracting production scheduling, to production data collection and cost control, without overlooking the Industry 4.0 connection of the production plants and automatic warehouses.

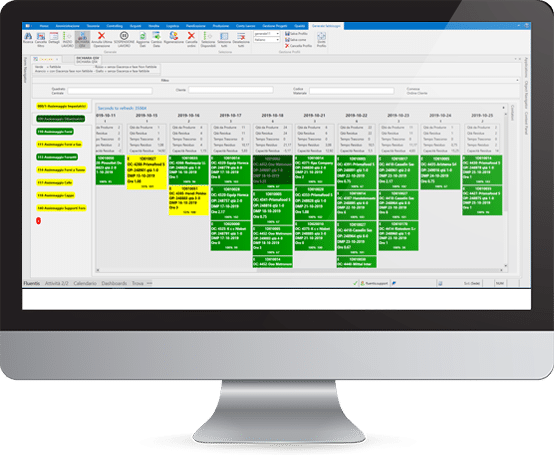

Fluentis ERP’s MES (Manufacturing Execution System) has been designed by implementing a large series of parameters for the integrated management of data from production processes that most impact a company’s profitability. In the Production area of Fluentis, we can see how the documents and data relating to the production orders – launched but not necessarily executed – define how each department and location execute production activity.

The materials, the phases and sub-phases, the equipment and in general all the supporting documentation is designed to make the execution of the activity as automated, organized and fluid as possible.

The main algorithm of good management specialized in the Production area is defined by the MRP, the planning system that deals with verifying the correct allocation of materials and resources necessary for carrying out the production activity. The MRP algorithm is configured according to a large series of parameters to adapt better to the type of production reality facing the company.